Food packaging

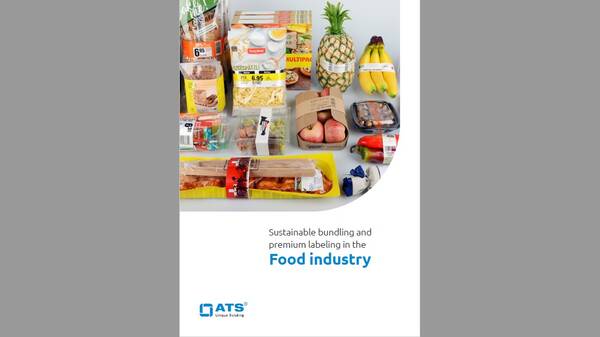

Banding is sustainable packaging in the food industry: bundling, labeling and premium labeling.

Banding is flexible, minimizes packaging and reduces energy consumption along the entire value chain. Bands hold all types of food securely together, enhance the product, carry information and optimize processes.

For which products would you like to optimize your packaging?

Banding is branding, labeling and tamper proofing

Whether suhshi or bento boxes, snack, salad or meal trays, disposable or reusable bowls: adhesive-free banding is the optimal solution for branding, labeling and tamper evidence. The optionally pre-printed, 15 to 100 mm wide paper sleeves can be precisely and fully automatically printed with variable information such as product name, production and best-before dates, 1D or 2D codes or ingredient lists during the banding process.

Bands are better than cardboard sleeves

In contrast to cardboard slipcases, bands are only sealed during the packaging process and thus closed. Either according to predefined lengths or flexibly depending on the product volume and desired band tension. This makes banding much more flexible than cardboard slipcases. The adjustable band tension ensures that bands do not slip even without adhesive. Further advantages of banding compared to cardboard sleeves:

- No additional labels thanks to just-in-time printing

- No heat development thanks to ultrasonic welding

- Easy recycling and less packaging volume

- High productivity thanks to automation

- Product visibility guaranteed

- Processing of various band materials on the same machine

Branding and labeling

Product enhancement through branding with banding: Banded products stand out at the point of sale. The bands, which are up to 100 mm wide, can be printed on both sides in 12 colors and offer plenty of space for information - from storytelling to barcodes. Variable information such as production and best-before dates, 1D or 2D codes or ingredients are printed on the bands just-in-time during the banding process. The infinitely adjustable and versatile band tension keeps the band in place - even without adhesive or additional labels. Banding has even more advantages over cardboard sleeves:

- No heat development thanks to ultrasonic welding

- Easy recycling and less packaging volume

- High productivity thanks to automation

- Visibility of the products guaranteed

- Processing of various band materials on the same machine

Customer-friendly multipacks

A band is frustration-free packaging. The infinitely adjustable sealing force ensures the right mix of easy tearing and security. Consumers benefit from the simplest possible product handling: there is no need to laboriously cut open films, simply open by hand. No further waste separation is necessary: the bands can simply be recycled via the correct cycle - paper or mono plastic, depending on the band type.

Bundling logistical units with minimal packaging

Paper bands replace plastic bags, tubular film and shrink film when bundling. Depending on requirements, bands made of thin, recyclable film can also be used. Bands minimize packaging from the producer to the distribution center to the point of sale. Another advantage: bands can be opened by hand. There is no risk of injury from sharp tools when unpacking at the POS.

Branding, labeling and tamper protection

Adhesive-free banding is the perfect solution for branding, labeling and tamper protection for patisserie and baked goods of all kinds. High-quality, pre-printed paper sleeves up to 100 mm wide add value to the product. They can be precisely printed with additional information such as product name, best-before date, barcode or a list of ingredients during the banding process. Thanks to precisely adjustable band tension, bands do not slip even without adhesive or additional labels. Banding has even more advantages over cardboard pushers:

- No heat development thanks to ultrasonic welding

- Easy recycling and less packaging volume

- High productivity thanks to automation

- Visibility of the products guaranteed

- Processing of various banding materials on the same machine

Bands close cardboard trays

Paper bands hold winged trays of apples, citrus fruits, tomatoes, avocados and other fruit and vegetables securely together. Thanks to ideal band tension and flexible band length, the fruit and vegetables are held together in such a way that they do not bump into each other and cause dents during transportation. The bands also act as advertising and information carriers. This packaging solution benefits the environment, consumers and, thanks to automation, also productivity.