Banding of cardboard, carton and paper

Wide bands and ultrasonic sealing technology from ATS guarantee gentle, safe and efficient bundling of printed and unprinted products made of cardboard, carton and paper.

Bundling solid and corrugated cardboard, cardboard and paper with wide bands and ultrasonic sealing technology from ATS offers proven advantages over conventional strapping with strapping tape: The bands, which are up to 100 mm wide and can be printed in advance and just-in-time if required, protect the surfaces and edges of corrugated cardboard, folding cartons, displays, printed matter, flyers, banknotes and many other paper products - always with the minimum amount of packaging material and, wherever practical, with paper bands.

In which area do you work?

Bands protect surfaces and edges of paper, cardboard and paperboard products

Strapping stacks of corrugated cardboard, cardboard or paper with wide bands and ultrasonic sealing technology from ATS offers proven advantages over strapping with conventional PP and PET bands: the bands, which are up to 30 mm wide, protect the surfaces and edges of corrugated cardboard and folding cartons, displays and other products. This minimizes waste and simplifies handling. This is a decisive competitive advantage that is particularly important for high-quality packaging (e.g. for cosmetics packaging with a high degree of finishing or high-quality toys, food or consumer electronics).

Extra-strong banding paper for bundling heavy stacks of corrugated cardboard

For applications where very tight and tear-resistant strapping is required, two paper bands have proven to be particularly suitable: A 30 mm wide and 120 g/m2 thick kraft paper with a coating of TruePaper (PBS12030TP) and a kraft paper, also 30 mm wide and 120 g/m2 thick, with a PP coating (PBS12030PP). Both papers are extremely tear-resistant and, in combination with the ultrasonic sealing technology from ATS, achieve extremely strong sealing and therefore high tensile strength. Bundling stacks weighing 15 kg is no problem with either paper. The paper with the TruePaper coating, which is exclusively available from ATS, can be given the recycling code PAP 22 and recycled in the normal paper cycle.

Leading machine manufacturers integrate ATS banding technology into their packaging machines

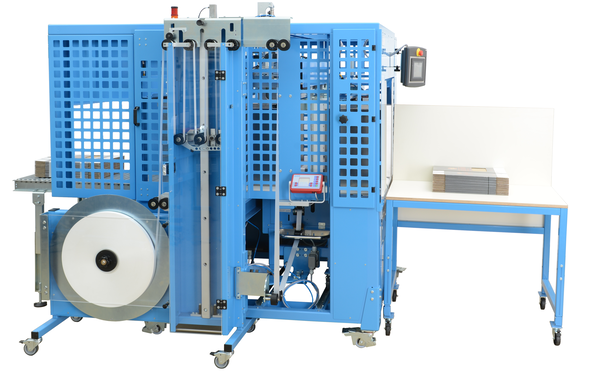

Examples of machines that are available with ultrasonic banding technology from ATS include the SPEEDPACK automatic packaging machine SPEEDPACK from BOBST, the POWERPACKER from BAHMÜLLER and the UCB corrugated cardboard strapping machine from MOSCA. Instead of conventional strapping machines, they can all be supplied with optional integrated banding machines from ATS. ATS-Tanner Banding Systems has the standalone US-2000 AST-MDM banding machine and the fully automatic US-2000 TRC-900 with jumbo dispenser in its range. Both machines have a 900 x 500 mm arc and process bands made of paper or film with a width of 30 mm.

Banding machines for strapping corrugated cardboard

Bands protect edges and surfaces when bundling printed products

Banding machines from ATS bundle and band printed products in print shops and in print finishing with a minimum of packaging material and without damaging edges and surfaces. The banding machines process bands made of paper and film. If required, the bands can be printed with dynamic information just-in-time in advance and during the banding process. For example, with customer-specific information or for identification, sorting and logistics, quality control or automation.

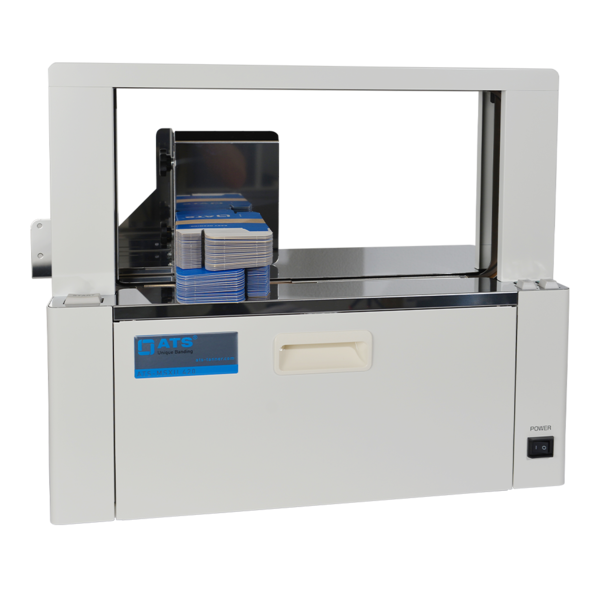

Paper bands replace plastic film when bundling playing cards, greeting cards and envelopes

Printed or unprinted paper bands are the environmentally and customer-friendly alternative to plastic packaging when bundling playing cards, greeting cards, envelopes and similar products. Depending on the requirements, ATS banding machines take over the banding or, in fully automatic production lines, the counting, aligning, stacking or other process steps.

Fully automatic alignment and bundling of label stacks

The banding machines of the LBM series are developed and built for the fully automatic, highly efficient and gentle bundling of label stacks. Specially developed and built for use in label printing plants, the banding machines align wet-glue labels, cut & stack labels and other labels and bundle them with bands made of paper or film.

Stay flexible when banding with table-top models and standalone machines

The mobile, space-saving banding machines from ATS are easy to move and can be positioned anywhere. The optionally printed paper bands, which can also be printed just-in-time if required, bundle and finish print products of all kinds tightly, securely and without damaging edges and surfaces

> To the table-top models and stand-alone machines for banding printed products

Fully automatic aligning, stacking, bundling, banding and printing as part of the production line

Fully automatic banding machines perform additional functions such as conveying, counting, aligning, pressing, stacking or just-in-time printing with variable information. They are part of the production line and are either fully integrated or become end-of-line automation at the end of the production line. For example, directly on a compensating stacker.

> To the fully automatic machines and systems for banding printed products

Banding with the highest standards of security, reliability and performance

Companies that specialize in the production and processing of banknotes and securities place very high demands on the security, reliability and performance of their packaging systems. ATS has many years of experience in global cooperation with private and state players in security printing and cash management. The banding machines and systems used often perform not only banding, but also other functions such as counting or just-in-time printing of bands for traceability and security, inventory and management, automation or anti-fraud measures.